- 22 June 2023

- Back to overview

Industrial RAM

Clarification of terms

Like "Server RAM" or "Desktop RAM", the term "Industrial RAM" is not uniformly defined. Industrial-grade memory, such as for a steel mill, civil engineering, the medical field, or aviation, doesn't necessarily differ by unique form factors, higher capacities, or other performance-related product properties. Instead, they primarily differ through requirements for certain qualitative characteristics. Often, they must withstand particularly challenging conditions, such as shocks, vibration, or heat. In this article, we will delve into the essential requirements for Industrial RAM and briefly introduce how these are specifically achieved.Table of Contents

- Requirements for Industrial RAM

- Component Transparency and Compatibility Through

- Fixed Bill of Materials (BOM) - Reliability and Longevity Through

- The use of particularly high-quality components

- Adapted design and manufacturing features - Long-term Availability Through

- Long-term supply contracts

- Stock keeping and obsolescence management

- EOL & PCN Management

- Component Transparency and Compatibility Through

- Conclusion

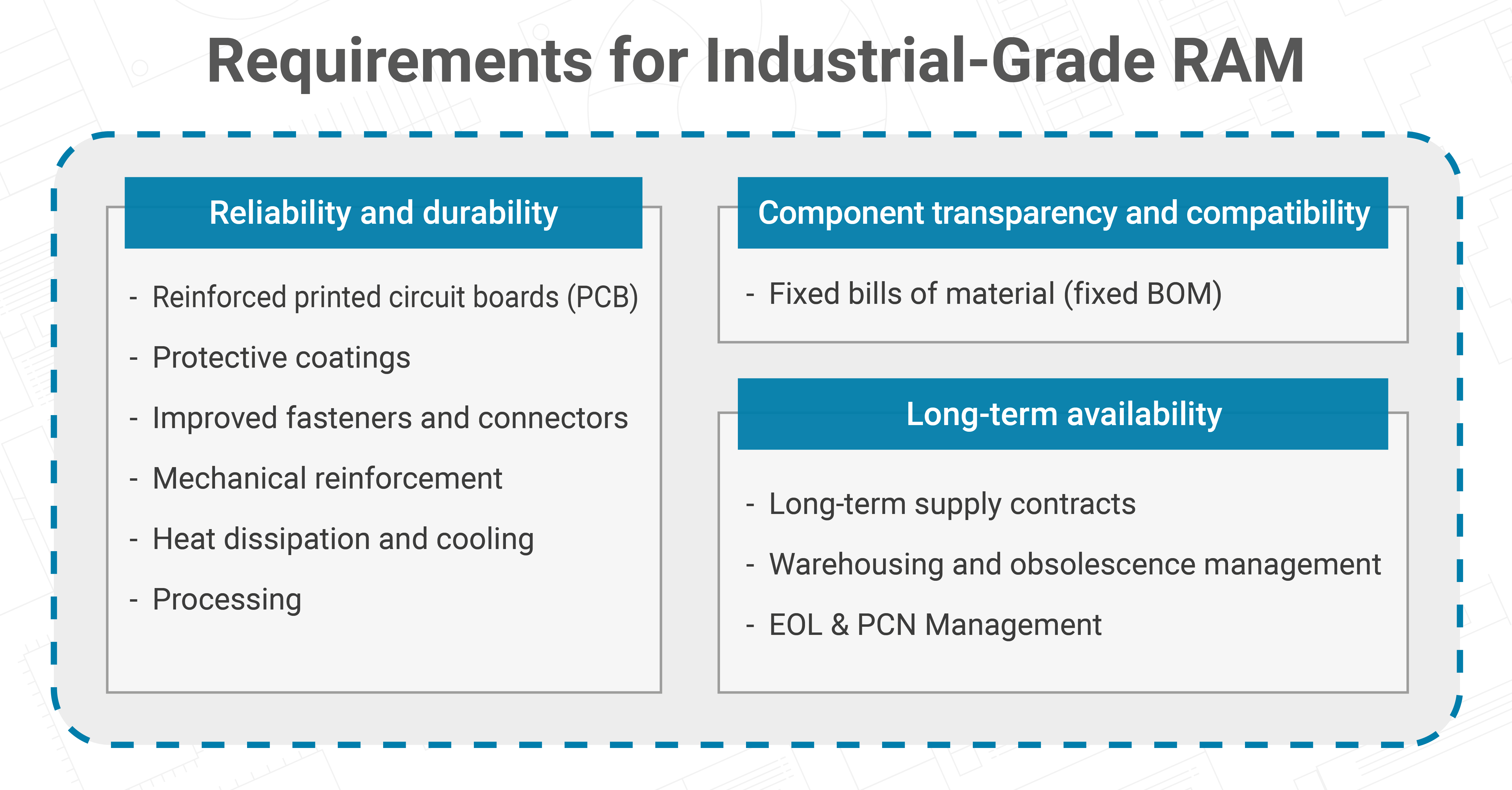

Requirements for Industrial RAM

Depending on the application and area of use, the requirements for industrial-grade memory differ greatly from each other. Generally, the following factors are particularly relevant in the field of industrial applications:

1. Component Transparency and Compatibility

With over 25 years of experience, we understand the importance of fixed BOMs for Industrial RAM.

Fixed Bill of Materials (BOM)

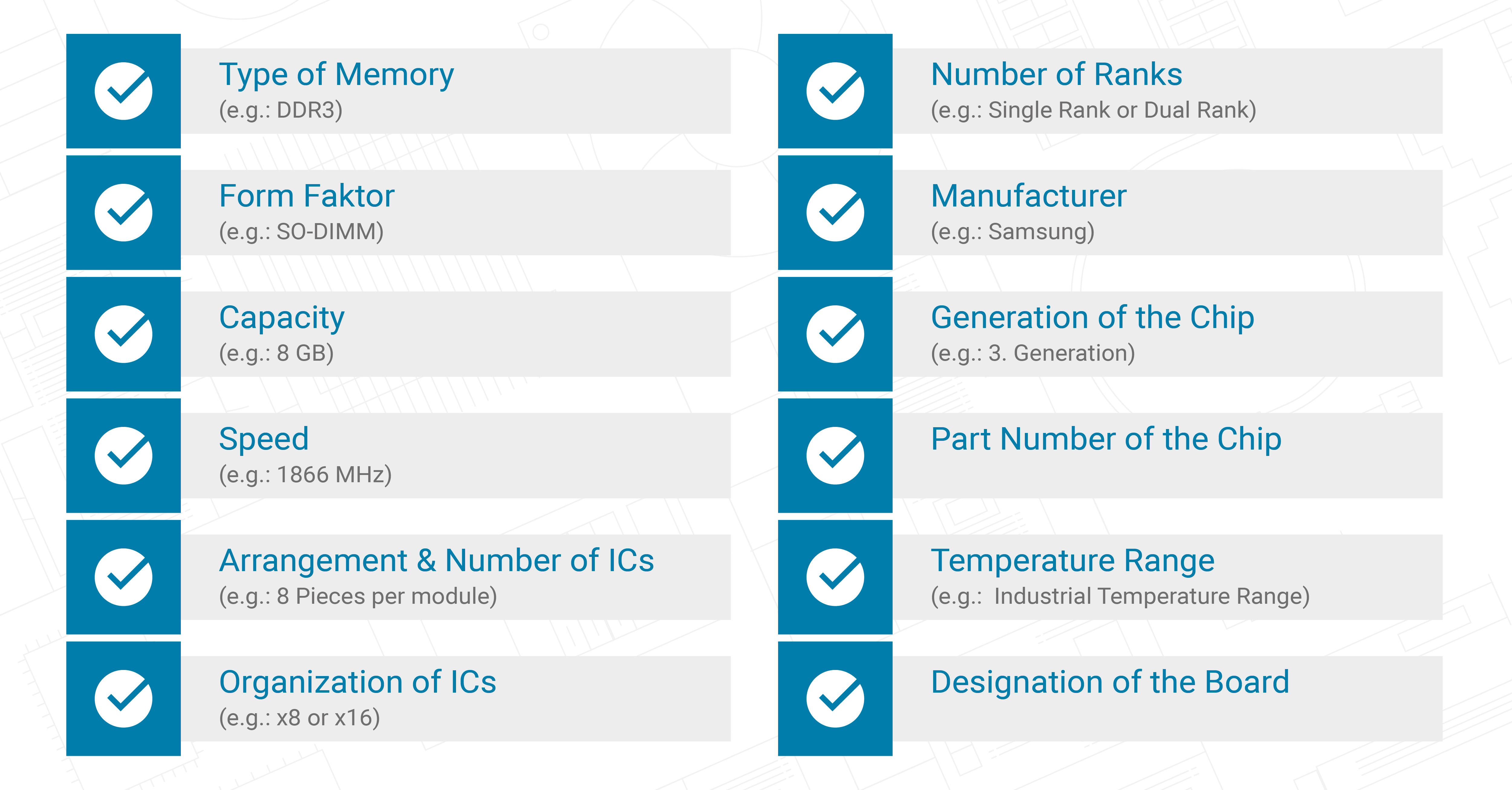

While server and consumer RAM (for use in desktop PCs or notebooks) are usually more flexible regarding the components used, industrial applications require a consistent BOM to ensure that each RAM module exhibits the exact same characteristics in every production cycle. These fixed BOMs are often referred to as fixed BOM (Bill of Materials).

Advantages of a fixed BOM

The fixed BOM guarantees the reliability and consistency of components in industrial applications. Moreover, it reduces the risk of compatibility issues or failures due to component variations. Also, a fixed BOM favors the long-term availability and interchangeability of RAM modules. Industrial applications often require a longer lifespan of the used components. Although the fixed BOM itself is not a guarantee for the long-term availability of components, it ensures that manufacturers and users know exactly which components are used in the RAM modules. This, in turn, brings benefits for planning future needs and procurement of replacement parts.

2. Reliability & Longevity

Because malfunctions or failures of components can have significant effects on production processes, safety, and costs, the reliability and longevity of memory for industrial use are particularly important. For instance, the failure of memory in safety-critical applications, e.g., due to the failure of the computer in a control center for emergency services or also in medical applications, can potentially cost lives.

Extended Temperature Range

We also count the extended temperature range for which the memory must be designed as part of reliability and longevity. Because industrial environments can be subject to extreme temperature fluctuations: from very high temperatures near machines to extremely low temperatures in cold storage. For this reason, Industrial RAM modules are designed to operate in extended temperature ranges, while server or consumer RAM modules are rather developed for moderate environmental conditions.

Overview of Temperature Ranges

| Range | Temperature Range |

| Commercial | 0 °C to 70 °C |

| Industrial | -40 °C to 95 °C |

| Automotive | -40 °C to 125 °C |

| Military/Aviation | -40 °C to 125 °C |

Improved reliability and longevity are achieved in industrial RAM through various factors, including:

The selection of reliable, durable, and high-quality components in the production of RAM modules contributes to increased reliability. This includes

printed circuit boards (PCBs) with better thermal conductivity and greater resistance to temperature fluctuations.For example, PCBs made from high-temperature-resistant materials like polyimide or those with improved heat dissipation, such as aluminum core PCBs, can be used.

High-quality soldering materials with better adhesion, less oxidation, and better thermal conductivity are also important.

High-quality plastics for components (e.g., for housing materials) that are more resistant to environmental influences such as UV radiation, humidity, or chemical effects, and

high-quality materials for electronic components (e.g., resistors, capacitors, and memory chips) that have better electrical properties, tighter tolerances, and longer lifespans are used. Specific examples include tantalum capacitors or precision-engineered resistors.

RAM modules must be designed and manufactured considering the specific requirements of industrial applications. This can include a more robust design, protection against environmental influences, or the use of materials and technologies that work better in demanding environments.

Reinforced PCBs

A thicker or reinforced PCB can help increase the mechanical strength of the RAM module and make it less susceptible to bending, warping, or breakage under stress.

Protective coatings

RAM modules can be provided with protective coatings such as conformal coatings or encapsulants to protect them from moisture, dust, chemical effects, and other environmental stresses. These coatings can help extend the life of the modules in demanding environments.

Improved fastening and connection elements

A more robust design can also include improved fastening and connection elements, such as screw connections or special connectors that hold up better in harsh environments and ensure a more reliable connection.

Mechanical reinforcement

RAM modules can be provided with additional mechanical reinforcements to increase their structural stability and resistance to vibrations and shocks. This can include metal or plastic frames, struts, or heat sinks that give the module additional strength.

Heat dissipation and cooling

Improved heat dissipation and cooling can help reduce the thermal load on the RAM modules and extend their life in demanding environments. This can be achieved by using special heat sinks, thermal conducting materials, or improved heat dissipation in the PCB design.

Processing

Particularly precise processing of individual components (e.g., when milling individual components) can contribute to reliability and longevity.

Error correction methods (ECC)

In some industrial applications, the use of RAM modules with error correction methods (Error Correcting Code, ECC) can increase reliability. ECC RAM can detect and correct errors that occur during memory access, reducing the likelihood of data loss or system crashes.

Samsung ODECC

ODECC stands for "On-Die Error Correcting Code" and is a technology developed by Samsung for error correction in memory modules. Unlike traditional ECC technology, where the error correction is performed by a separate chip on the memory module, error correction with ODECC occurs directly on the memory chip (also referred to as "Die").

More about Samsung ODECC

Samsung ODECC is integrated directly into the memory chip, providing error correction at a deeper level and potentially offering less latency and better performance.

- Efficiency

Since ODECC operates directly on the die, it can respond to and correct errors more quickly and efficiently. This can improve the overall performance of the memory module. - Space saving

By performing error correction directly on the die, the need for additional chips on the module is eliminated, saving space on the PCB. This can contribute to more compact modules or higher memory density on the module. - Reliability

By integrating ODECC into the memory chip itself, errors can be detected and corrected more quickly. This can lead to higher reliability and longevity of the memory module.In summary, ODECC is an evolution of traditional ECC technology that aims to integrate error correction directly onto the memory chip. This can improve performance, efficiency, and reliability while saving space on the PCB.

3. Long-term availability

Long-term availability of components such as RAM is especially important for manufacturing and industrial applications. Industrial plants and machines often have a long lifespan that can extend over many years or even decades. During this time, companies need to be able to maintain their facilities and procure replacement parts or components, such as RAM, as needed.

Changes to hardware components can lead to compatibility problems or instability, especially in complex systems. Long-term availability of RAM and other components ensures that companies can continue to access proven and tested components without worrying about adjustments or potential problems.

To ensure long-term availability, the following aspects should be particularly considered:

Through our long-standing partnerships with leading manufacturers, as a distributor for industrial memory, we can offer our customers long-term supply contracts.

As part of our service, we guarantee 100% stock availability throughout the project period and stable long-term prices through framework contracts.

Manufacturers use PCNs (Product Change Notification) to inform about technical changes to a product. Thanks to close cooperation with all relevant manufacturers, we are familiar with the roadmaps and ensure proactive monitoring of the component lifecycle.

As part of our obsolescence management, we ensure that our customers are informed about all product changes and product discontinuations. We also take care of the immediate provision of the appropriate successor. In this way, we ensure that the quality and cost structure of the product are not negatively affected.

Conclusion

The term "industrial RAM" is not uniformly defined. However, memory for industrial needs often have special requirements for certain quality characteristics. These include those that improve 1) component transparency and compatibility, 2) reliability and longevity, and 3) long-term availability.

Our Business Unit Memorysolution Industrial has been dealing with the needs of various industries for over 25 years. Depending on customer requirements, we manufacture memory modules with IC components directly from the manufacturer in industrial quality, including industrial RAM. This means that we deal in detail with your requirements and find the optimal industrial RAM for your company.

If you have any further questions about industrial RAM, please feel free to contact our industry experts with your questions.

-

High-Performance Computing Infrastructure to Support Molecular ResearchMaximilian Jaud | 10 February 2025The system configuration enables highly complex computations to run in parallel while efficiently processing large datasets.Mehr lesen

High-Performance Computing Infrastructure to Support Molecular ResearchMaximilian Jaud | 10 February 2025The system configuration enables highly complex computations to run in parallel while efficiently processing large datasets.Mehr lesen -

High-Performance Virtualization Platform based on ProxmoxMaximilian Jaud | 31 January 2025Redundant high-performance platform capable of virtualizing around 200 servers for diverse applications, featuring fast NVMe storage for active workloads and large HDD storage for long-term archiving.Mehr lesen

High-Performance Virtualization Platform based on ProxmoxMaximilian Jaud | 31 January 2025Redundant high-performance platform capable of virtualizing around 200 servers for diverse applications, featuring fast NVMe storage for active workloads and large HDD storage for long-term archiving.Mehr lesen -

High-Performance and Fail-Safe System for CybersecurityMaximilian Jaud | 16 December 2024To support complex security processes, the customer required a high-performance, scalable IT infrastructure.Mehr lesen

High-Performance and Fail-Safe System for CybersecurityMaximilian Jaud | 16 December 2024To support complex security processes, the customer required a high-performance, scalable IT infrastructure.Mehr lesen -

High-Performance IT Infrastructure to Support ResearchMaximilian Jaud | 29 November 2024High-performance and specialised HPC infrastructure for Forschungszentrum Jülich.Mehr lesen

High-Performance IT Infrastructure to Support ResearchMaximilian Jaud | 29 November 2024High-performance and specialised HPC infrastructure for Forschungszentrum Jülich.Mehr lesen -

Hardware Requirements in the Age of Edge and Cloud ComputingMaximilian Jaud | 28 October 2024Deductions from the McKinsey Technology Trends Outlook 2024 – Part 2Mehr lesen

Hardware Requirements in the Age of Edge and Cloud ComputingMaximilian Jaud | 28 October 2024Deductions from the McKinsey Technology Trends Outlook 2024 – Part 2Mehr lesen -

Effects of Generative AI on Hardware RequirementsMaximilian Jaud | 28 October 2024Deductions from the McKinsey Technology Trends Outlook 2024 – Part 1Mehr lesen

Effects of Generative AI on Hardware RequirementsMaximilian Jaud | 28 October 2024Deductions from the McKinsey Technology Trends Outlook 2024 – Part 1Mehr lesen -

Focus on technologiesMaximilian Jaud | 1 August 2024the relevance of HBM and 3D stackingMehr lesen

Focus on technologiesMaximilian Jaud | 1 August 2024the relevance of HBM and 3D stackingMehr lesen -

Supermicro X14 - Simply explainedMaximilian Jaud | 15 July 2024Supermicro introduces the new X14 server seriesMehr lesen

Supermicro X14 - Simply explainedMaximilian Jaud | 15 July 2024Supermicro introduces the new X14 server seriesMehr lesen -

A Look at Samsung's PM1743 SSDMaximilian Jaud | 15 July 2024Security and Reliability Solutions for Enterprise EnvironmentsMehr lesen

A Look at Samsung's PM1743 SSDMaximilian Jaud | 15 July 2024Security and Reliability Solutions for Enterprise EnvironmentsMehr lesen -

SIE and SED Encryption in KIOXIA SSDsMaximilian Jaud | 15 July 2024KIOXIA has enabled these functions by default, providing all users with enhanced data security.Mehr lesen

SIE and SED Encryption in KIOXIA SSDsMaximilian Jaud | 15 July 2024KIOXIA has enabled these functions by default, providing all users with enhanced data security.Mehr lesen -

PCRAMMaximilian Jaud | 1 December 2023Learn more about the potential of FeRAM as a powerful replacement for EEPROM solutionsMehr lesen

PCRAMMaximilian Jaud | 1 December 2023Learn more about the potential of FeRAM as a powerful replacement for EEPROM solutionsMehr lesen -

ReRAMMaximilian Jaud | 1 December 2023Learn more about the potential of FeRAM as a powerful replacement for EEPROM solutionsMehr lesen

ReRAMMaximilian Jaud | 1 December 2023Learn more about the potential of FeRAM as a powerful replacement for EEPROM solutionsMehr lesen